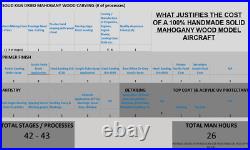

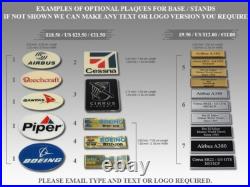

“You never really own a PlaneArts model – you merely look after it for the next generation”. Dimensions of the model are. 16.10 INCHES (40.90 CM). 17.00 INCHES (43.20 CM). This model replica is painstakingly hand carved and then hand painted out of solid kiln dried mahogany wood (from renewable sources) by our highly experienced and talented craftsmen at our Filipino owned factory near the original Clark Air Base in Pampanga and takes about 9-10 weeks to manufacture. Production in our factory is supervised by our own resident British Pilot who ensures that exact blueprints are used for these meticulously detailed scale models custom manufactured and precisely engineered to your exact specifications and that will be cherished by all. The model will be exactly as you see in the above and below images in terms of detailing doors, windows, lights, control surface markings, antennas etc. Color and size so we would kindly ask you to study the images very carefully (if you require higher resolution images please ask) to make sure that the model as you see is the 100% the same version you require or expect. If there are changes that you require or mistakes or deference’s in relation to the real aircraft before ordering, please message us and we will setup an alternative listing to match your own requirements. We request your understanding on this matter due to the fact that these handmade models are traveling in many cases halfway around the world and any misunderstandings or mistaken expectations must be addressed at this as point of time as we cannot be held responsible for the costs involved in returning and replacing the model. Our models are “works of art” and not to be confused with mass made plastic kits or diecast (die cast) look-alikes. We are proud Filipino’s exporting to all parts of the globe and creating employment opportunities in an impoverished part of our country. 100% handmade models naturally come at a higher price than off the shelf, plastic or diecast (die cast) models but it may interest you to know that an average regular size fixed wing or helicopter model takes on average a total of 26 dedicated Man Hours of work to produce. During this time the model transitions through over 40 different manufacturing stages and processes. The 26 hours are not consecutive and require in-between many days (and in some cases weeks) of drying and curing time as they pass from one department to another making the overall production time from an outsiders point of view appear rather lengthy. Given these facts the time period we quote for production alone is very standard for our type of industry and among our close competitors. If you are interested in what goes into making these models, there follows a summary process schedule and video. Production video will open in a new window. The fully assembled model comes with a stained solid mahogany (or mahogany with steel arm) stand and is ready to display on your desk, bookcase or wherever you desire. The photographs you see have not been manipulated or digitally edited – they are exactly as the model looks in real life, but unfortunately even digital photography cannot do full justice to the look and feel of the model once you receive it! PlaneArts have been producing models for over 20 years which are honed to perfection by the dexterity of our Skilled Master Craftsmen and carefully checked at all stages of manufacture by our dedicated Quality Assurance Team. Due to a high level of demand and the huge diversity of aircraft types and liveries most models are made to order and take about 9-10 weeks to produce (excluding National and Public Holidays). Fully traceable and insured against damage or loss. You can even upgrade and personalize your model with a fully customized transparent interior to match your seats, colors, instrument panel and all other important interior details. Alternatively, we can copy any current or historic commercial or military airplane or helicopter that has ever flown just by giving us images or photos. Each meticulously detailed scale model is custom manufactured and precisely engineered to your exact specifications. We will build you a model that will not only meet your expectations but will go far beyond and with detail that will amaze you! Our Customer Service Team will then help you with questions you may have and upon request update you on the status of your order. Our Production Team will work with you personally during construction until your model is ready to taxi on its journey to your own door in its foam fitted heavy duty export packaging. Short 360-300: A Reliable Workhorse in Air Cargo Operations. The Short 360-300 stands out as a stalwart in the world of air cargo transportation, revered for its robust design, operational efficiency, and capability to deliver cargo reliably to remote and challenging environments. Manufactured by Short Brothers PLC, this twin-turboprop aircraft has carved a niche in the cargo industry, particularly valued by operators like Air Cargo Carriers for its versatility and dependable performance. The Short 360-300 features a rugged design optimized for cargo operations, with a high-wing configuration and twin Pratt & Whitney Canada PT6A-65AR turboprop engines, each generating 1,100 shaft horsepower. This configuration enables the aircraft to achieve a cruise speed of approximately 220 knots (253 mph) and operate efficiently over short to medium-range routes. The 360-300 is well-suited for accessing smaller airstrips and delivering cargo swiftly and reliably to destinations not easily reached by larger aircraft. Cargo Capacity and Configuration. Central to the Short 360-300’s appeal in air cargo operations is its generous cargo capacity and flexible loading options. Operators like Air Cargo Carriers leverage the aircraft’s versatility by configuring the interior to suit specific cargo requirements, ensuring efficient loading and unloading procedures at both primary and secondary airports. The cockpit of the Short 360-300 is equipped with essential avionics and instrumentation tailored for cargo operations. Standard equipment typically includes navigation aids, communication radios, weather radar, and basic flight management systems. These systems enable pilots to navigate safely through diverse weather conditions and airspace environments while maintaining operational efficiency. The Short 360-300 excels in a variety of air cargo missions, including. Humanitarian Aid: Supporting humanitarian missions by delivering critical supplies, medical equipment, and relief materials to disaster-stricken areas with limited infrastructure. Short Brothers PLC has a longstanding reputation for designing aircraft with a strong emphasis on safety and reliability. The Short 360-300 incorporates robust construction materials and redundant systems to ensure operational safety and withstand the rigors of frequent cargo operations. Comprehensive maintenance programs and stringent safety protocols further enhance the aircraft’s reliability, contributing to its excellent track record in air cargo transportation. Since its introduction, the Short 360-300 has played a pivotal role in expanding air cargo capabilities, particularly in regions requiring reliable and efficient transport solutions. Its versatility, combined with economical operational costs, continues to make it a preferred choice among cargo operators worldwide, including Air Cargo Carriers, who rely on its dependable performance to maintain critical supply chains and logistics networks. In conclusion, the Short 360-300 remains a cornerstone in air cargo operations, recognized for its durability, versatility, and operational efficiency. Whether transporting cargo across remote regions, supporting humanitarian efforts, or facilitating industrial logistics, the 360-300 proves its worth as a reliable workhorse in the air cargo industry. With its robust design, adaptable cargo configurations, and commitment to safety, the Short 360-300 continues to uphold its legacy as a trusted asset in global aviation logistics.